Testing Equipment Insights & Buyer's Guide

Testing equipment constitutes an important part of many sectors and is necessary to guarantee the security and thus the dependability and the quality of the produced goods or materials. In this regard, the present article is aimed at delineating the purpose of the testing equipment, the types of testing equipment available, their primary attributes, and the uses that the testing equipment serves in the quest for quality assurance during materials tests. Whether integrated in production, in the medical field, or in construction, studying the variety of testing instruments and knowing their capabilities helps experts in the field to collect the information needed to address the problem.

Introduction to Testing Equipment

Testing equipment proves to be essential in an industrial environment where precision is valued and production meets certain standards. Such devices are manipulatives used to measure and ascertain the adequacy of material and product function, strength, and quality. There are quite a number of devices available for testing, which include mechanical and electrical gadgets, thus enabling companies to test more accurately and effectively. This chapter prepares the reader to appreciate the functional utilities and advantages of testing equipment as applied to different industries.

Importance of Testing Equipment in Various Industries

Testing equipment is relevant and operated in many industries, each of which has its particular demands and criteria. For instance, in manufacturing industries, testing machines are used to evaluate the resistance and the safety of materials, allowing for the production of good quality products, which is in accordance with what is expected. In medical fields, correct testing equipment is fundamental in the analysis and monitoring of patients’ health conditions. The construction sector uses testing apparatus to assess material qualities, such as the strength of steel rebar or the adhesion of concrete-preformed polymer joints. In all these cases, effective dissemination of information is crucial to preventing product failures and optimizing the process of production

Overview of Popular Testing Equipment Types

There are several types of testing equipment that are used for specific purposes, and each type has particular conditions to be adhered to while performing a test. Among the most frequently used are digital test machines, which are effective in giving accurate readings and offer many data handling options. There are also automatic testing machines that are easy to use and produce results instantly, allowing workflows to be productive. Special equipment that adheres to ASTM standards is intended for high-performance goals. And even a wide battery of tests, from simplest evaluations of materials and complex systems, can be performed with the help of these handy implements.

How Testing Equipment Enhances Quality Control

The use of testing equipment contributes greatly to the enhancement of quality control due to the accuracy and reliability of the results provided. Such equipment allows the study of materials in an orderly fashion, enhanced testing, far from the safety and performance levels only. Such tools provide detailed information on the quality of a product that helps in managing and servicing the product effectively. Moreover, for these more advanced devices, software integration enhances quality control due to real-time analytical capabilities and the ability to monitor performance tracks online

Testing Equipment: Important Characteristics to Evaluate

Accuracy: Its Significance

Accuracy is an important aspect of test equipment selection because it affects the quality of the test data obtained. Accurate testing equipment assures that the measurements meet the required specifications for the industry. Failure to obtain reliable results may render industries vulnerable to lawsuits, fines, or even the recall of defective products. For that reason, organizations must consider the accuracy of any testing equipment, especially that will be used in either materials testing or analyzing the functioning of electrical equipment. Trust in testing because of its accuracy incorporates more than just assurance against violations of some provisions of the law.

Durability: Choosing Equipment That Lasts Long

Durability should be a consideration when buying testing equipment because it affects the life expectancy of the regalia purchased. Encouragingly, modern designers are cognizant of this fact and thus build testing machines that are strong and resistant to extreme wear and tear that is expected from repeated usage and external environmental factors. This is very useful in the industries because the instruments are handled many times, and have a wide range of tests performed on them. In addition, with the purchase of instruments that are durable and sturdy, business activities, or rather testing activities, are sustained without any disruption or interference in the procedural compliance cycle, which translates into less replacement demand as well.

Ease of Use: Important Considerations on User-Friendly Models

Some focus on user-friendly characteristics of test equipment, which contributes to the effectiveness of the laboratories. Instruments that do not require complexities during the operator’s setup are the best for ease and accuracy of carrying out tests. Automatic adjustments to a standard level, reading devices such as digital meters, and the use of computer programs to perform the tests are examples of such techniques. Therefore, any company's operations are prone to lower training costs as well as low operator-induced error rates. This alleviates the system processes apart from perpetuating affirmative construction of test data in a manner that is able to cross all the relevant devices or tools within the targeted industry.

Testing Equipment Applications in Various Sectors

Manufacturing: Quality Assurance and Regulation

Components and products undergo rigorous quality and regulatory checks in every manufacturing process. Towards this end, testing equipment is inevitable. Using the equipment, quality checks are conducted to test the sturdiness, usability, and functionality of the materials and components. Manufacturers don’t want defective products to be launched in the market, and they try to minimize flaws as much as possible. They are porous, meaning that automatic ones can be outdone with the tried and tested sophisticated ones, but accuracy is compromised when using the current models of the same equipment that are available. Costing is also less than the previous models, as already lengthy speculative bubbles in the pricing. In other words, how the product should be made and delivered at the same time interfaces with how the user makes and delivers it, and how much goodness of the product, especially the one defined by the user, is achieved.

Healthcare: Safety and Efficiency Standards

Testing instruments in the field of healthcare are used in the investigation of the functionality as well as dependability of devices, ranging from medical appliances used for diagnosis to the manufacture of medicines that save lives. Testing in the health industry is a very delicate matter since testing directly influences the health of the person or the outcome of some treatment process. f Having regard to the stringent regulatory requirements on healthcare products, such technologies allow the marketer to remove any possible doubts conscious of the public, which tries to enhance the quality of documentation, health, and well-being of the population.

Construction: Exemplifying Performance by Testing Material Strength

Where construction is the focus, testing machines and devices are quite indispensable in proving that the materials used in the construction area are sound and safe. Apparatuses are used to evaluate the materials, such as composites, concrete, and steel, to discern their strength and behavior under proposed loadings. This is particularly significant in the construction of buildings and similar structures, as these materials have to successfully deal with external and internal forces expected during the structure’s lifetime. With a view to minimizing financial and structural losses resulting from failure to perform such technical works, the finishing companies would encourage adherence to the standards and better functionality and durability of the structure.

Emerging Examples of Recent Development in Equipment for Testing

Testing Process Automation Beyond Limits and Its Improvements

Applying automation in any sector is revolutionary, and testing equipment is no exception in boosting efficiency and aggressive precision. Automated testing systems are in high demand because they are efficient in complex procedures with little or no supervision required. These enhanced user-interactivity systems can perform a multitude of testing from basic mechanical to sophisticated electronic tests. All these tools engage in activities that are redundant and increase the efficiency of work by releasing the population from other tasks, which may result in the performance of low-quality tests or accidents. What is where you want to be and why; it helps you to arrest the trend to exist in the demand and supply zone, while the strategies of resource allocation are made to their optimal level.

Environmentally Friendly Design for Testing Instruments

Sustainable design in testing instruments is now at the forefront of conversion, as most of industries are becoming more responsible for the environment. Most already developed modern test equipment is increasingly being manufactured to ensure they are organic and energy-saving, thereby reducing the ecological impact. In addition to helping meet this regulation, this change also aids in attaining the goals of corporate social responsibility. With the use of sustainable designs, manufacturers of testing tools may provide products that are environmentally friendly and at the same time economical, thus providing the capacity to perform incurrence of long-term environmental and economic burdens without affecting the function or the reliability of the test.

Frequently Asked Questions (FAQs)

What types of testing machines are available in the market?

The market offers a comprehensive range of testing machines designed to meet various industry standards. Categories of these machines include mechanical testers, electrical testers, and advanced solutions for specific applications. Each type is capable of assessing different parameters, ensuring that you can determine the right tool for your needs. For example, tensile testers are used to evaluate the strength of materials, while electrical testing equipment is essential for verifying the performance of electronic devices. This extensive selection allows users to choose reliable testing solutions that cater to their specific requirements.

How do I determine the suitable testing equipment for my needs?

To determine the suitable testing equipment, you must first assess the specific testing requirements of your project. Start by identifying the type of materials or products you will be testing, as this will guide you toward the appropriate tester category. Additionally, consider the key attributes you need from the equipment, such as accuracy, reliability, and ease of use. Researching industry standards can also provide insights into what types of testing machines are commonly used in your field. Furthermore, consulting with service and support teams from equipment manufacturers can help ensure that you make an informed choice.

What is the maintenance required for testing tools?

Maintenance for testing tools is crucial to ensure reliable performance over time. Regular checks should include calibration to verify that the equipment is producing accurate results. Additionally, it’s important to clean and inspect the tools for any signs of wear or damage. Depending on the type of equipment, you may also need to replace components periodically to maintain optimal functionality. Establishing a maintenance schedule can help extend the lifespan of your testing machines and ensure compliance with industry standards. Furthermore, many manufacturers provide support and guidance on effective maintenance practices.

How do electrical testing products differ from mechanical testing tools?

Electrical testing products and mechanical testing tools serve different purposes and are designed to assess various properties. Electrical testers focus on verifying the performance and safety of electrical devices, measuring parameters such as voltage, current, and resistance. In contrast, mechanical testing tools evaluate the physical properties of materials, such as tensile strength, hardness, and elasticity. Understanding these differences is key to selecting the right equipment for your specific application. While both categories contribute to quality assurance, they utilize different methods and technologies to provide reliable testing results.

Why is it important to use reliable testing equipment?

Using reliable testing equipment is essential for ensuring the accuracy and consistency of test results. High-quality testers not only help in assessing product quality but also in maintaining compliance with industry standards. Inaccurate measurements can lead to faulty products, safety issues, and financial losses. Moreover, investing in reliable equipment can enhance your laboratory's reputation and credibility in the industry. By choosing suitable testing solutions, you can streamline your testing processes and ensure that your products meet the expected performance criteria. Ultimately, this reliability contributes to better management of testing operations and customer satisfaction.

Economical Fan Testing Equipment With Good GuaranteeUS$ 3000 - 10000MOQ: 1 SetJinan Wangtebei Instrument And Equipment Co.,ltd1 Yr

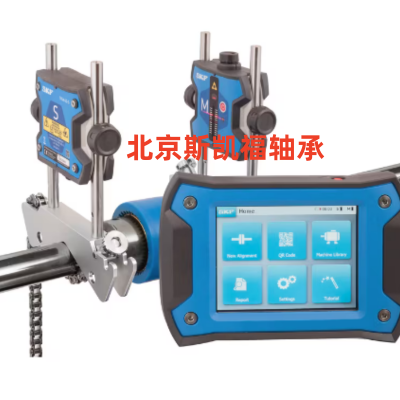

Economical Fan Testing Equipment With Good GuaranteeUS$ 3000 - 10000MOQ: 1 SetJinan Wangtebei Instrument And Equipment Co.,ltd1 Yr SKF Axis Alignment Instrument TKSA 51 Testing EquipmentNegotiableMOQ: 100 PiecesBrand Name: SKFUsage: Auto Testing MachineBeijing SKF Bearing Trading Co., Ltd.1 Yr

SKF Axis Alignment Instrument TKSA 51 Testing EquipmentNegotiableMOQ: 100 PiecesBrand Name: SKFUsage: Auto Testing MachineBeijing SKF Bearing Trading Co., Ltd.1 Yr 700bar to 1000bar High Pressure Water Jetting Machine Hydro Testing EquipmentUS$ 8888.00MOQ: 1 Setmachine type: HIGH PRESSURE CLEANERcondition: Newplace of origin: shenyang, Chinabrand name: RELIABLEShenyang Reliable Technology Co., Ltd.1 Yr

700bar to 1000bar High Pressure Water Jetting Machine Hydro Testing EquipmentUS$ 8888.00MOQ: 1 Setmachine type: HIGH PRESSURE CLEANERcondition: Newplace of origin: shenyang, Chinabrand name: RELIABLEShenyang Reliable Technology Co., Ltd.1 Yr Frequency Converter Friendly Interfac Automatic Test EquipmentUS$ 1000 - 3000MOQ: 1 UnitType: DC/AC InvertersXiAn Wisdom Computer Info&tech Co., Ltd8 Yrs

Frequency Converter Friendly Interfac Automatic Test EquipmentUS$ 1000 - 3000MOQ: 1 UnitType: DC/AC InvertersXiAn Wisdom Computer Info&tech Co., Ltd8 Yrs ROSEMOUNT 1055-01-10-20-30NegotiableMOQ: 1 PieceBrand Name: ROSEMOUNTPlace of Origin: United StatesModel Number: 1055-01-10-20-30Xiamen Amikon Limited1 Yr

ROSEMOUNT 1055-01-10-20-30NegotiableMOQ: 1 PieceBrand Name: ROSEMOUNTPlace of Origin: United StatesModel Number: 1055-01-10-20-30Xiamen Amikon Limited1 Yr Heated Enclosure for Automotive Testing Equipment in Freezing Temperature ScenariosNegotiableMOQ: 10 PiecesMaterial: Other, High-grade stainless steel or customizableDimensions: Custom sizes available upon requestApplication: Automotive testing in freezing conditionsTemperature Range: Operates from -40°C to +50°CShandong Huaning Electric Heating Technology Co.,Ltd1 Yr

Heated Enclosure for Automotive Testing Equipment in Freezing Temperature ScenariosNegotiableMOQ: 10 PiecesMaterial: Other, High-grade stainless steel or customizableDimensions: Custom sizes available upon requestApplication: Automotive testing in freezing conditionsTemperature Range: Operates from -40°C to +50°CShandong Huaning Electric Heating Technology Co.,Ltd1 Yr National Instruments GPIB-140A: Your Modern Bridge to Legacy Test EquipmentUS$ 3216.00MOQ: 1 BladeI/O Number: NI GPIB-140APlace of Origin: AmericaModel Number: NI GPIB-140ACondition: NEWXiamen Xiongba E-commerce Co., LTD1 Yr

National Instruments GPIB-140A: Your Modern Bridge to Legacy Test EquipmentUS$ 3216.00MOQ: 1 BladeI/O Number: NI GPIB-140APlace of Origin: AmericaModel Number: NI GPIB-140ACondition: NEWXiamen Xiongba E-commerce Co., LTD1 Yr Hengna Laboratory Heavy Duty Steel Workbench for Research Institute – Precision Workstation for Fatigue Testing EquipmentUS$ 100 - 200MOQ: 5 SetsMaterial: MetalUsage: Office, School, Study, OtherCondition: NewCustomized: CustomizedLuoyang Hengna Office Furniture Co., Ltd.1 Yr

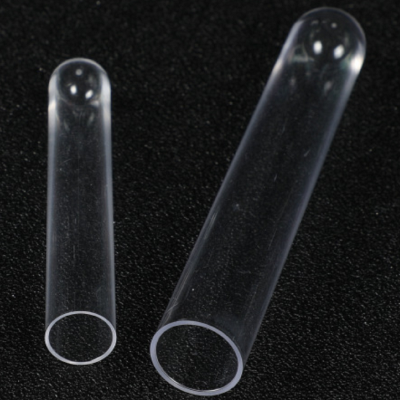

Hengna Laboratory Heavy Duty Steel Workbench for Research Institute – Precision Workstation for Fatigue Testing EquipmentUS$ 100 - 200MOQ: 5 SetsMaterial: MetalUsage: Office, School, Study, OtherCondition: NewCustomized: CustomizedLuoyang Hengna Office Furniture Co., Ltd.1 Yr Test TubeUS$ 0.011 - 0.016MOQ: 50000 PiecesBrand Name: HEKPlace of Origin: ChinaModel Number: 1Daoran Trade (Jilin) Co., Ltd,2 Yrs

Test TubeUS$ 0.011 - 0.016MOQ: 50000 PiecesBrand Name: HEKPlace of Origin: ChinaModel Number: 1Daoran Trade (Jilin) Co., Ltd,2 Yrs Testing EquipmentUS$ 100 - 5,000MOQ: 1 SetPlace of Origin: Henan, ChinaBrand Name: zhengchengModel Number: nonstandardAnyang Zhengcheng Machinery Co., Ltd.5 Yrs

Testing EquipmentUS$ 100 - 5,000MOQ: 1 SetPlace of Origin: Henan, ChinaBrand Name: zhengchengModel Number: nonstandardAnyang Zhengcheng Machinery Co., Ltd.5 Yrs Test EquipmentUS$ 1,300 - 130,000MOQ: 1 SetPlace of Origin: Shandong, ChinaBrand Name: HighlandModel Number: YST 380Power: HydraulicJi'nan High Land Hydraulic Pump Co., Ltd.5 Yrs

Test EquipmentUS$ 1,300 - 130,000MOQ: 1 SetPlace of Origin: Shandong, ChinaBrand Name: HighlandModel Number: YST 380Power: HydraulicJi'nan High Land Hydraulic Pump Co., Ltd.5 Yrs Test EquipmentNegotiableMOQ: 1 SetType: Engine AnalyzerVoltage: 220V/380VPower: 3KWCertification: ISO9001:2008Taian Haiyu Machinery Co., Ltd.5 Yrs

Test EquipmentNegotiableMOQ: 1 SetType: Engine AnalyzerVoltage: 220V/380VPower: 3KWCertification: ISO9001:2008Taian Haiyu Machinery Co., Ltd.5 Yrs Test Equipment Mechanical Vibration Test EquipementUS$ 100,000 - 119,000MOQ: 1 SetBrand Name: HongjinPlace of Origin: ChinaModel Number: GP-562Power: ElectronicHongjing Test Instrument Co., Ltd.5 Yrs

Test Equipment Mechanical Vibration Test EquipementUS$ 100,000 - 119,000MOQ: 1 SetBrand Name: HongjinPlace of Origin: ChinaModel Number: GP-562Power: ElectronicHongjing Test Instrument Co., Ltd.5 Yrs Textile Testing EquipmentUS$ 5,016 - 5,469MOQ: 1 SetPlace of Origin: Zhejiang, ChinaBrand Name: TENGFEIModel Number: TF-260Machine Type: Textile TesterHangzhou Tengfei Sewing Machinery Co., Ltd.5 Yrs

Textile Testing EquipmentUS$ 5,016 - 5,469MOQ: 1 SetPlace of Origin: Zhejiang, ChinaBrand Name: TENGFEIModel Number: TF-260Machine Type: Textile TesterHangzhou Tengfei Sewing Machinery Co., Ltd.5 Yrs IEC60529 Waterproof Testing EquipmentNegotiableMOQ: 1 SetPlace of Origin: Guangdong, ChinaBrand Name: CXModel Number: CX-2Power: ElectronicShenzhen Chuangxin Instruments Co., Ltd.5 Yrs

IEC60529 Waterproof Testing EquipmentNegotiableMOQ: 1 SetPlace of Origin: Guangdong, ChinaBrand Name: CXModel Number: CX-2Power: ElectronicShenzhen Chuangxin Instruments Co., Ltd.5 Yrs Scratch Resistance Testing EquipmentUS$ 5.00 - 15.00MOQ: 1 SetBrand Name: GBPIPlace of Origin: Guangdong, ChinaModel Number: Gx-C1Power: ElectronicThickness Tester Co., Ltd5 Yrs

Scratch Resistance Testing EquipmentUS$ 5.00 - 15.00MOQ: 1 SetBrand Name: GBPIPlace of Origin: Guangdong, ChinaModel Number: Gx-C1Power: ElectronicThickness Tester Co., Ltd5 Yrs SELON BRIX Testing EquipmentUS$ 202 - 220MOQ: 1 SetPlace of Origin: Shanghai, ChinaBrand Name: SELONModel Number: SE-2WAJShanghai Selon Scientific Instrument Co., Ltd.5 Yrs

SELON BRIX Testing EquipmentUS$ 202 - 220MOQ: 1 SetPlace of Origin: Shanghai, ChinaBrand Name: SELONModel Number: SE-2WAJShanghai Selon Scientific Instrument Co., Ltd.5 Yrs Moisture Testing EquipmentsNegotiableMOQ: 1 UnitPlace of Origin: Maharashtra, IndiaBrand Name: ContechModel Number: CBB, CAH SeriesPower: ElectronicContech Instruments Limited5 Yrs

Moisture Testing EquipmentsNegotiableMOQ: 1 UnitPlace of Origin: Maharashtra, IndiaBrand Name: ContechModel Number: CBB, CAH SeriesPower: ElectronicContech Instruments Limited5 Yrs Medical Elisa Test EquipmentNegotiableMOQ: 1 PieceBrand Name: ADDCAREModel Number: ADC ELISA 200/400/600Place of Origin: Shandong, ChinaYantai Addcare Bio-Tech Limited Company5 Yrs

Medical Elisa Test EquipmentNegotiableMOQ: 1 PieceBrand Name: ADDCAREModel Number: ADC ELISA 200/400/600Place of Origin: Shandong, ChinaYantai Addcare Bio-Tech Limited Company5 Yrs Hydrostatic Test EquipmentUS$ 90 - 95MOQ: 20 PiecesPlace of Origin: Jiangsu, ChinaBrand Name: XingYunModel Number: XY3000JType: Other, hydrostatic test equipmentChangzhou XingYun Electronic Equipment Co., Ltd.5 Yrs

Hydrostatic Test EquipmentUS$ 90 - 95MOQ: 20 PiecesPlace of Origin: Jiangsu, ChinaBrand Name: XingYunModel Number: XY3000JType: Other, hydrostatic test equipmentChangzhou XingYun Electronic Equipment Co., Ltd.5 Yrs Transformer Hydrostatic Test EquipmentNegotiableMOQ: 1 PiecePlace of Origin: Shaanxi, ChinaBrand Name: YunyiModel Number: XY-901Xi'an Yunyi Instrument Co., Ltd.5 Yrs

Transformer Hydrostatic Test EquipmentNegotiableMOQ: 1 PiecePlace of Origin: Shaanxi, ChinaBrand Name: YunyiModel Number: XY-901Xi'an Yunyi Instrument Co., Ltd.5 Yrs Fire and Flammability Testing EquipmentUS$ 3,600 - 4,500MOQ: 1 SetPlace of Origin: Guangdong, ChinaBrand Name: AUTOSTRONGModel Number: AUTO-SPAShenzhen Autostrong Instrument Co., Ltd.5 Yrs

Fire and Flammability Testing EquipmentUS$ 3,600 - 4,500MOQ: 1 SetPlace of Origin: Guangdong, ChinaBrand Name: AUTOSTRONGModel Number: AUTO-SPAShenzhen Autostrong Instrument Co., Ltd.5 Yrs Balancing Machine in Test EquipmentUS$ 100 - 100,000MOQ: 1 SetPlace of Origin: Shanghai, ChinaBrand Name: JpModel Number: PHWQ-3000HPower: ElectronicShanghai Jianping Dynamic Balancing Machine Manufacturing Co., Ltd.5 Yrs

Balancing Machine in Test EquipmentUS$ 100 - 100,000MOQ: 1 SetPlace of Origin: Shanghai, ChinaBrand Name: JpModel Number: PHWQ-3000HPower: ElectronicShanghai Jianping Dynamic Balancing Machine Manufacturing Co., Ltd.5 Yrs Paint Test EquipmentsUS$ 5,500 - 20,000MOQ: 1 SetCondition: NewPlace of Origin: Shandong, ChinaBrand Name: SFModel Number: SFRC600BQingdao Sefe Trading Co., Ltd.5 Yrs

Paint Test EquipmentsUS$ 5,500 - 20,000MOQ: 1 SetCondition: NewPlace of Origin: Shandong, ChinaBrand Name: SFModel Number: SFRC600BQingdao Sefe Trading Co., Ltd.5 Yrs Lead Purchaser inquired about soil lab testing equipment slurry tank2025-12-09 02:13:51

Lead Purchaser inquired about soil lab testing equipment slurry tank2025-12-09 02:13:51 Procurement Lead is sourcing Portable Hair And Skin Analyser/Skin Testing Equipment2025-12-07 14:14:11

Procurement Lead is sourcing Portable Hair And Skin Analyser/Skin Testing Equipment2025-12-07 14:14:11 Business Owner is sourcing Melt Flow Index Testing Equipment (MFI tester)2025-12-11 00:21:04

Business Owner is sourcing Melt Flow Index Testing Equipment (MFI tester)2025-12-11 00:21:04 Business Owner is sourcing CR816 diesel fuel injection test equipment for sale2025-12-07 16:13:28

Business Owner is sourcing CR816 diesel fuel injection test equipment for sale2025-12-07 16:13:28 Business Owner negotiating terms for PVB film test equipment-steel ball2025-12-10 18:42:49

Business Owner negotiating terms for PVB film test equipment-steel ball2025-12-10 18:42:49 Telephone Line Test EquipmentNegotiableMOQ: 5000 PiecesPlace of Origin: Guangdong, ChinaBrand Name: CHEETA or OEMModel Number: CT-TW126Type: Hotel PhoneShenzhen Cheeta Technology Co., Ltd.5 Yrs

Telephone Line Test EquipmentNegotiableMOQ: 5000 PiecesPlace of Origin: Guangdong, ChinaBrand Name: CHEETA or OEMModel Number: CT-TW126Type: Hotel PhoneShenzhen Cheeta Technology Co., Ltd.5 Yrs Professional Skin Testing Equipment ( Hair and Skin Testing Equipment )US$ 300 - 1,500MOQ: 1 SetCertification: Medical CEPlace of Origin: Beijing, ChinaBrand Name: OstarBeautyModel Number: OB-SA 02Ostar Beauty Sci-Tech Co Ltd5 Yrs

Professional Skin Testing Equipment ( Hair and Skin Testing Equipment )US$ 300 - 1,500MOQ: 1 SetCertification: Medical CEPlace of Origin: Beijing, ChinaBrand Name: OstarBeautyModel Number: OB-SA 02Ostar Beauty Sci-Tech Co Ltd5 Yrs Laobratory Fume Hood in Testing EquipmentUS$ 200 - 1,000MOQ: 1 SetMaterial: Other, Metal, All steel/Stainless steel/FRPMetal Type: Other, Cold-rolled steel sheetSize: 1200*800*2350Place of Origin: Guangdong, ChinaGuangzhou Boka Lab System Tech. Co., Ltd.5 Yrs

Laobratory Fume Hood in Testing EquipmentUS$ 200 - 1,000MOQ: 1 SetMaterial: Other, Metal, All steel/Stainless steel/FRPMetal Type: Other, Cold-rolled steel sheetSize: 1200*800*2350Place of Origin: Guangdong, ChinaGuangzhou Boka Lab System Tech. Co., Ltd.5 Yrs Injector Pump Test Equipment DTS205US$ 3,480 - 3,660MOQ: 1 SetBrand Name: DONGTAIModel Number: DTS205Power: ElectronicTaian Dongtai Machine Manufacturing Co., Ltd.5 Yrs

Injector Pump Test Equipment DTS205US$ 3,480 - 3,660MOQ: 1 SetBrand Name: DONGTAIModel Number: DTS205Power: ElectronicTaian Dongtai Machine Manufacturing Co., Ltd.5 Yrs CE Certified Turbocharger Testing EquipmentUS$ 6,000 - 10,000MOQ: 1 UnitPlace of Origin: Shandong, ChinaBrand Name: PHOENIXModel Number: RYQ-16APower: ElectronicJinan Bodihao Mechanical Equipment Co., Ltd.5 Yrs

CE Certified Turbocharger Testing EquipmentUS$ 6,000 - 10,000MOQ: 1 UnitPlace of Origin: Shandong, ChinaBrand Name: PHOENIXModel Number: RYQ-16APower: ElectronicJinan Bodihao Mechanical Equipment Co., Ltd.5 Yrs SLL Facial Skin Testing EquipmentUS$ 1 - 2,300MOQ: 1 PieceCertification: CEPlace of Origin: Guangdong, ChinaBrand Name: SLLModel Number: SA8Guangzhou SLL Beauty Technology Limited5 Yrs

SLL Facial Skin Testing EquipmentUS$ 1 - 2,300MOQ: 1 PieceCertification: CEPlace of Origin: Guangdong, ChinaBrand Name: SLLModel Number: SA8Guangzhou SLL Beauty Technology Limited5 Yrs Portable Transformer Oil Test EquipmentUS$ 1,000 - 5,000MOQ: 1 SetPlace of Origin: ChinaBrand Name: ctbuModel Number: SYPower: ElectronicChongqing Technology And Business University S&T Developing Ltd.5 Yrs

Portable Transformer Oil Test EquipmentUS$ 1,000 - 5,000MOQ: 1 SetPlace of Origin: ChinaBrand Name: ctbuModel Number: SYPower: ElectronicChongqing Technology And Business University S&T Developing Ltd.5 Yrs